Applications

SCADA systems are used in various industries, including:

- Power generation and distribution:Monitoring and controlling power grids.

- Oil and gas:Monitoring and controlling pipelines, refineries, and other facilities.

- Water and wastewater treatment:Monitoring and controlling water supply and wastewater treatment plants.

- Manufacturing:Monitoring and controlling industrial processes in factories and other manufacturing facilities.

- Transportation:Monitoring and controlling traffic, rail, and other transportation systems.

Benefits

- Improved efficiency and productivity:

By automating tasks and providing real-time data, SCADA systems can improve efficiency and productivity.

By minimizing waste and optimizing processes, SCADA systems can reduce operating costs.

By providing real-time monitoring and control, SCADA systems can help ensure the safety of workers and the environment.

- Enhanced decision-making:

By providing real-time data and historical records, SCADA systems can help operators make better decisions.

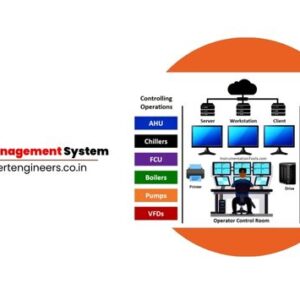

- SCADA System: What is it? (Supervisory Control and Data Acquisition)

Reviews

There are no reviews yet.